Fluid Handling & Safety Equipment

Kernow Oils supplies a complete range of Fluid Handling & Safety Equipment to help businesses across Cornwall and the South West manage oils, lubricants, and coolants efficiently and safely. From oil transfer systems to spill-proof dispensing and drum handling tools, we make fluid movement cleaner, safer, and fully compliant.

Why fluid handling safety matters

Improper storage or transfer of industrial fluids can lead to spills, contamination, and workplace injuries. Using the right equipment not only protects your staff and the environment but also ensures product integrity and compliance with UK safety standards.

- Prevent spills and contamination: Use sealed pumps and containers for clean, precise transfer.

- Protect your team: Reduce lifting injuries and exposure with ergonomic drum handling tools.

- Maintain lubricant quality: Avoid cross-contamination and extend lubricant life.

- Ensure compliance: Meet HSE and EA safety standards.

- Increase efficiency: Speed up maintenance and fluid transfer operations.

Whether you’re filling, draining, or transferring fluids, Kernow Oils can equip your business with safe, durable, and compliant handling solutions.

Our Fluid Handling & Safety Equipment Range

We supply and install equipment from leading manufacturers to ensure safe, efficient, and compliant fluid management throughout your site:

- Manual and electric oil transfer pumps

- Air-operated drum and IBC dispensing systems

- Grease guns, hose reels, and no-drip couplers

- Drum trolleys, lifts, and ergonomic handling aids

- Safety containers and sealed dispensing units

- Spill trays, drip pans, and containment funnels

- Flammable liquid cabinets and safety signage

How We Work

- Site Assessment: Our specialists review your current fluid storage and transfer setup.

- Recommendation: We propose tailored equipment options to improve safety and compliance.

- Supply & Installation: Delivery and installation of fluid handling systems on-site.

- Training: We provide staff guidance on correct handling and maintenance practices.

- Ongoing Support: Optional service plans for calibration, inspection, and equipment upkeep.

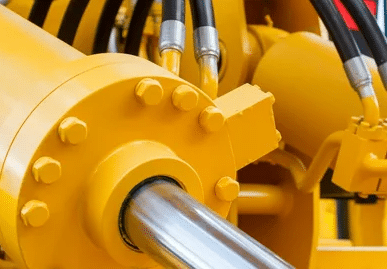

Case Study – Marine Engineering Firm, Falmouth

Challenge: Frequent oil spills during refilling of hydraulic systems on dockside machinery.

Solution: Installed closed-loop oil transfer system with sealed pump and drip-free couplers.

Result: Zero spills for 6 months, improved worker safety, and faster refuelling operations.

“Kernow Oils provided expert advice and robust equipment — our refilling process is now safer and cleaner than ever.” — Marine Engineering Firm

Commonly Asked Fluid Handling FAQs

What’s the safest way to transfer oil from drums or IBCs?

Always use a sealed transfer system with a suitable pump and hose set to prevent contamination and spillage. Manual pouring is not recommended.

Do you provide installation and training?

Yes — Kernow Oils offers full installation and hands-on training for all supplied systems to ensure your team operates them safely and efficiently.

Are your pumps compatible with all fluid types?

We supply pumps suitable for oils, coolants, grease, AdBlue, and other industrial fluids — each matched to the correct material compatibility and flow rate.

Can I integrate your systems into existing storage setups?

Yes — our engineers can retrofit pumps, hose reels, and containment trays to fit existing tanks and IBC setups without disruption.

Upgrade your fluid handling and safety systems today

Contact Kernow Oils for advice, supply, and installation of Fluid Handling & Safety Equipment tailored to your site. Our expert team will help improve efficiency and compliance across your operation.

Request a Fluid Handling Consultation

Tel: 01736 757002 · Email: info@kernow-oils.co.uk

Related:

Oil Containment Advice ·

Fluid Testing & Oil Recycling ·

Industrial Oils ·

Fluid Handling Safety Tips (Blog)