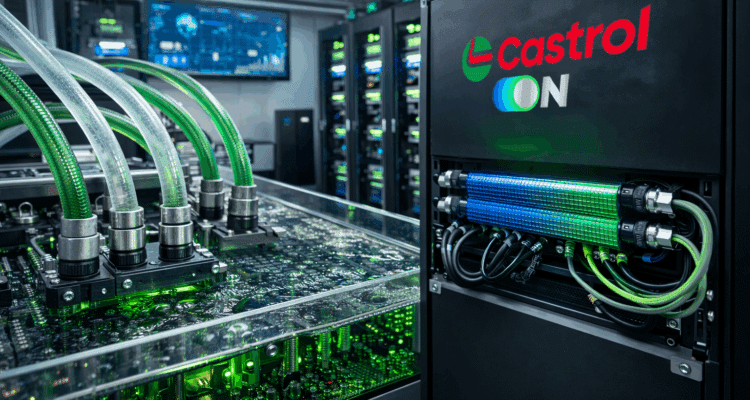

Immersion Cooling Systems Using Castrol ON -Pre-Checks

A Practical Guide for Data Centre Cooling Operations

As data centres continue to push power density higher with AI, HPC and edge workloads, Immersion Cooling Systems have become a critical pillar of next-generation Data Centre Cooling strategies. However, achieving long-term reliability and performance starts with one essential step: carrying out the correct pre-checks before introducing fluid into your system.

This guide outlines best-practice pre-check procedures for systems using Castrol ON Immersion Cooling Fluids, helping operators ensure safe operation, fluid integrity, and maximum thermal efficiency.

Why Pre-Checks Matter in Immersion Cooling

Immersion cooling systems rely on direct contact between IT hardware and dielectric fluid. Any contamination, incompatibility, or handling error can compromise:

-

Cooling efficiency

-

Hardware reliability

-

Dielectric performance

-

Fluid lifespan

-

Operational safety

Pre-checks ensure your data centre cooling infrastructure is fully prepared before filling your immersion tanks with Castrol ON.

Overview of Castrol ON Immersion Cooling Fluids

Castrol ON DC 15 and DC 20 are single-phase immersion cooling fluids designed specifically for closed-loop electronic cooling systems.

They deliver:

-

Excellent flow properties

-

High specific heat for efficient thermal transfer

-

Superior oxidative and hydrolytic stability

-

Outstanding dielectric performance

-

Compatibility with common construction metals

Before use, material compatibility with your immersion system should always be confirmed with your Castrol representative.

Safety First: Preparing Your Site and Team

Immersion cooling fluids must always be handled under formal safety procedures.

Operator Safety Requirements

Before handling Castrol ON:

-

Your HSSE (Health, Safety, Security & Environment) team should review all handling procedures

-

Safety Data Sheets (SDS) must be available on site

-

Operators must be trained and competent

-

PPE must be selected based on site risk assessments

Exposure Controls

Although Castrol ON fluids present low inhalation risk during normal operation, additional precautions should be taken during fluid transfer:

-

Ensure adequate ventilation

-

Use low-agitation transfer pumps

-

Avoid prolonged exposure

- Wear appropriate PPE

Pre-Checks Before Filling an Immersion Cooling System

Before introducing any immersion cooling fluid into a tank, the following checks should be completed.

1. System Inspection

Visually inspect the entire immersion cooling system:

-

Ensure tanks are clean and free from debris

-

Check for leaks or mechanical defects

-

Confirm there is no residue from previous fluids

-

Verify no manufacturing oils or contaminants remain

If contamination is present, a full system flush may be required. Always consult your system manufacturer for approved cleaning procedures.

2. Product Verification

-

Confirm the correct Castrol ON product is being used (DC 15 or DC 20)

-

Inspect containers for damage

-

Ensure seals are intact and unopened

-

Verify containers are clean and defect-free

3. Transfer Equipment Check

-

Ensure pumps are compatible with dielectric fluids

-

Confirm pumps are clean and contamination-free

-

Verify fittings, hoses, and couplings are suitable for immersion cooling fluid transfer

4. Safety and Environmental Controls

Before filling begins:

-

Ensure SDS documentation is available

-

Confirm PPE is worn by all operators

-

Verify spill kits are present at the filling location

-

Identify the waste stream and the disposal process

-

Ensure system manuals are available for reference

Filling the Immersion Cooling System

Always follow the manufacturer’s approved filling procedure for the immersion tank. Tanks and pipework must be clean, inspected, and ready to prevent contamination of the Castrol ON immersion cooling fluid.

Never introduce fluid into a system that has not passed inspection.

Ongoing Inspections During Operation

Once operational, regular inspections help maintain fluid health and cooling performance.

What to Look For

-

Fluid should appear clear and bright

-

Slight discolouration over time can be normal

-

Cloudiness or heavy discolouration may indicate contamination or degradation

If an abnormal appearance is detected, immediately contact your Castrol representative for technical guidance.

Summary: Immersion Cooling Pre-Check Checklist

Before introducing Castrol ON immersion cooling fluid into your data centre cooling system, confirm:

✔ SDS and PPE are available and in use

✔ Transfer pumps are clean and compatible

✔ Fluid containers are inspected and verified

✔ Immersion system is clean and leak-free

✔ Filling follows manufacturer procedures

✔ Spill kits are available

✔ Waste disposal processes are defined

✔ Regular inspections are scheduled

Building a Reliable Immersion Cooling Operation

Immersion cooling is transforming modern data centre cooling by enabling higher compute density, lower energy usage, and improved sustainability. But long-term success depends on discipline, process, and preparation.

By following these pre-checks, operators ensure that Castrol ON Immersion Cooling systems deliver:

-

Maximum thermal performance

-

Extended fluid life

-

Hardware protection

-

Operational safety

-

Regulatory compliance

Need Technical Support?

For SDS documentation, compatibility guidance, or pre-deployment advice, contact your Kernow Oils representative or email:

January 26, 2026