Site Preparation Guide for Immersion Cooling Fluid Systems Using Castrol ON

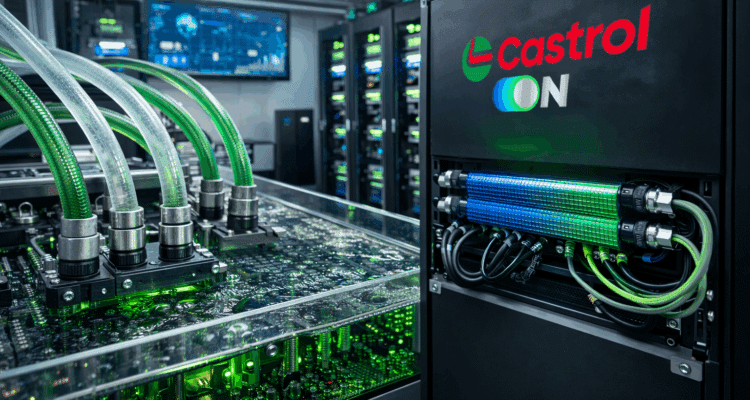

As data centres and high-performance computing environments continue to push power density limits, immersion cooling fluid technology is rapidly becoming the preferred solution for efficient thermal management. However, successful deployment starts long before the first tank is filled.

This guide explains how to properly prepare your site for Castrol ON immersion cooling fluid, ensuring safe handling, compliant storage, efficient logistics, and robust spill response.

Why Site Preparation Matters for Immersion Cooling Fluid

Immersion cooling systems rely on dielectric fluids to directly cool IT hardware. These fluids require specific handling, storage, and safety procedures to maintain performance, reliability, and regulatory compliance.

Castrol ON single-phase immersion cooling fluids (DC 15 and DC 20) are engineered for high-density compute environments, but proper site preparation is essential to:

-

Protect personnel

-

Maintain fluid integrity

-

Prevent contamination

-

Reduce operational risk

-

Ensure regulatory compliance

Storage Best Practices for Immersion Cooling Fluid

To maintain the integrity and dielectric performance of Castrol ON immersion cooling fluid, follow these storage guidelines:

Recommended Storage Conditions

-

Store in a dry, cool, well-ventilated area

-

Keep containers under cover

-

Avoid exposure to:

-

Direct sunlight

-

Freezing temperatures

-

Temperatures above 60°C

-

-

Keep containers tightly sealed until use

-

Reseal opened containers immediately

Outdoor Storage (If Unavoidable)

-

Lay drums horizontally

-

Prevent water ingress

-

Protect markings and labels

-

Avoid temperature fluctuations

Safe Handling of Castrol ON Immersion Cooling Fluid

Before receiving any immersion cooling fluid on site:

-

Ensure correct PPE is available

-

Prepare spill response equipment

-

Train staff on fluid handling procedures

Fluid Handling Safety Checklist

✔ Always wear appropriate PPE

✔ Avoid inhaling vapour or mist

✔ Never syphon by mouth

✔ No eating, drinking or smoking near fluids

✔ No ignition sources or sparks

✔ Ground equipment to prevent static discharge

✔ Use fire extinguishers rated for electrical environments

Spill Response Planning for Immersion Cooling Fluid

Even environmentally friendly dielectric fluids require correct spill management.

Site Spill Response Requirements

-

Fully stocked spill kits on site

-

Absorbent pads (not vermiculite or sand)

-

Absorbent booms for drain protection

-

Degreaser for slip prevention

-

Clearly labelled waste containers

-

Documented spill response plan

Small Spills

-

Wipe immediately

-

Use degreaser on residue

-

Avoid spray application

-

Reduce slip hazards

Large Spills

-

Isolate spill area with signage

-

Deploy absorbent booms

-

Prevent drain contamination

-

Ventilate area

-

Use absorbent pads

-

Dispose via a licensed contractor

Waste Disposal & Compliance

All used immersion cooling fluid must be:

-

Collected in labelled waste containers

-

Stored in compliant areas

-

Removed by licensed waste contractors

-

Disposed of in accordance with local regulations

♻ Proper waste management protects both your operation and the environment.

Why Choose Castrol ON Immersion Cooling Fluid?

Castrol ON is engineered specifically for modern data centre workloads:

-

High thermal stability

-

Low viscosity for efficient heat transfer

-

Long operational life

-

Hardware compatibility

-

Proven performance in hyperscale deployments

It is trusted globally for AI, HPC, blockchain, and edge compute environments.

Final Thoughts

Immersion cooling delivers major efficiency and sustainability gains, but only when supported by proper infrastructure and procedures. Preparing your site for Castrol ON immersion cooling fluid ensures:

-

Safe operations

-

Maximum fluid lifespan

-

Reduced downtime

-

Regulatory compliance

-

Faster deployment

If you are planning an immersion cooling deployment, site preparation is not optional — it is foundational.

Need Support?

For technical advice, fluid handling guidance, or deployment support, contact your Castrol representative or email:

January 19, 2026